PRODUCT OVERVIEW

Sanitary manual diaphragm valve is a common pipeline control valve. It has the characteristics of simple structure, beautiful appearance, fast disassembly and assembly, flexible operation and low fluid resistance. It can be operated manually through the handle. All steel parts are made of acid resistant stainless steel, and the seals are made of food silicone rubber or polytetrafluoroethylene, which meets the food hygiene specifications. The valve uses the valve stem to press the rubber film directly on the valve seat to stop or connect the vacuum system. It is widely used in many industries such as food, wine making, beverage, dairy products, fine chemicals, pharmacy and bioengineering.

PRODUCT ADVANTAGES

1. Due to the structural design of diaphragm valve itself, it is especially suitable for ultra pure medium or highly polluted and viscous liquid, gas, corrosive or inert medium.

2. When combined with control equipment, diaphragm valve can replace other traditional control systems, especially for solid and easily polluted inert media.

MAIN TECHNICAL PARAMETERS

| Nominal diameter | DN10-DN80,3/8"-3" |

| maximum temperature | -20 to 150 ℃ (depending on diaphragm) (stainless steel actuator) |

| maximum temperature | -20 to 130 ℃ (depending on diaphragm) (plastic actuator) |

| working pressure | Normally closed rubber 8bar, PTFE 6bar (option) Normally closed rubber 6bar, PTFE 4.5bar (standard) normally open and double acting rubber 8bar, PTFE 6bar

|

| Forged valve body | 1.4404/316L /1.4435 NB2 Fe≤0.5% |

| Cast valve body | 1.4404/316L /1.4435 NB2 Fe≤0.5% |

| Connection mode | Welding, quick assembly, flange, thread, you Ren, etc |

| Valve body structure | Straight through, tee, U-shaped tee, tank bottom valve, multi-channel diaphragm valve, etc |

| Diaphragm material | EPDM+PTFE(Double-deck)/EPDM/Silicon/FPM(Viton) |

| Connection standard | 3A BPE DIN SMS IDF ISO |

| Interface mode | KST220-1: welding type, KST220-2: welding card type, KST220-3: card type |

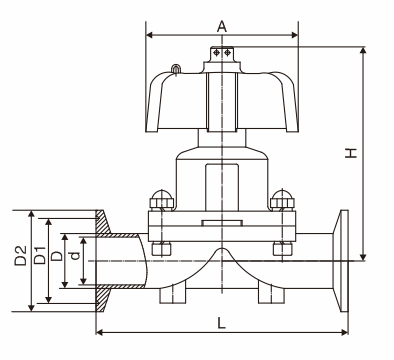

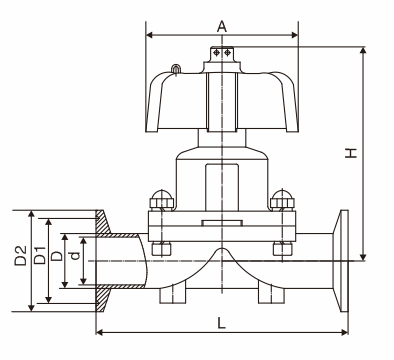

MAIN OVERALL CONNECTION DIMENSIONS

| DN | NPS | L | d | D | D1 | D2 | A | H | DH-L | DF-L | DF-L2 |

| 10 | 3/8 | 89 | 10 | 14 | 20.2 | 25.2 | 35 | 80 | 89 | - | - |

| 15 | 1/2 | 108 | 15 | 19 | 43.5 | 50.5 | 64 | 98 | 108 | 120 | 130 |

| 20 | 3/4 | 117 | 15.8 | 19.5 | 43.5 | 50.5 | 90 | 115 | 117 | 140 | 150 |

| 25 | 1 | 127 | 22.1 | 26 | 43.5 | 50.5 | 90 | 120 | 127 | 150 | 160 |

| 32 | 1-1/4 | 150 | 28 | 35 | 43.5 | 50.5 | 114 | 125 | 150 | 160 | 160 |

| 40 | 1-1/2 | 159 | 34.8 | 39 | 43.5 | 50.5 | 114 | 140 | 159 | 180 | 200 |

| 50 | 2 | 190 | 47.5 | 53 | 56.5 | 64 | 114 | 155 | 190 | 200 | 230 |

| 65 | 2-1/2 | 216 | 60 | 66 | 70.5 | 77.5 | 195 | 248 | 216 | 250 | 290 |

| 80 | 3 | 254 | 73 | 79 | 83.5 | 91 | 195 | 256 | 254 | 280 | 310 |