PRODUCT OVERVIEW

Pneumatic piston quick cut-off valve (referred to as piston cut-off valve for short) is the executive unit in the pneumatic unit combination instrument. It receives the signal from the regulating instrument to control the cutting and connecting of the fluid in the process pipeline or switching the flow channel. The product has the advantages of large operating force, novel valve body design, small flow resistance, large rated flow coefficient, large allowable differential pressure, excellent sealing performance and so on. Therefore, it is widely used in the production process automatic control and remote control system of petroleum, chemical industry, metallurgy, electric power, light textile and other industrial departments.

PRODUCT FEATURES

1. The pneumatic piston quick cut-off valve is composed of a pneumatic piston actuator and a straight stroke adjusting mechanism, and the middle is connected by a support. According to the type of regulating mechanism, pneumatic piston shut-off valve can be divided into three types: straight through single seat shut-off valve (zsqp type), straight through sleeve shut-off valve (zsqm type) and two position three-way shut-off valve (zsqn type). There are two kinds of pneumatic piston actuators: single acting (spring return) and double acting (double air inlet). Single acting actuator is adopted, and the action mode of the whole machine can be divided into air closed type (horizontal pipeline connected) and air open type (horizontal pipeline disconnected). Pneumatic piston cut-off valve has two sealing forms: hard seal and soft seal, which are applicable to different temperatures and pressures respectively.

2. When the signal pressure is zero, the valve core is in the initial state (normally open or normally closed) due to the preload of the spring (single acting only). When the actuator receives the signal pressure (0.4 ~ 0.6MPa), the piston generates thrust and compresses the spring to drive the push rod, valve body and valve core to the limit position to fully open or close the valve. Achieve the control of medium connection, cut-off or switching between pipelines in the pipeline. Equipped with two position three-way solenoid valve, the control of piston shut-off valve is more convenient and simple.

MAIN TECHNICAL PARAMETERS

| Nominal diameter DN(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|

| Rated flow coefficient Kv | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 |

| Rated stroke (mm) | 8 | 12 | 20 | 25 |

| Cylinder diameter (mm) | 75 | 100 | 150 |

| Allowable leakage | Hard seal (L/h) | Single seat, tee:1.2X10 -7 X Valve rated capacity sleeve: 5X10 -6 X Valve rated capacity |

| Soft seal | Class VI |

| Working temperature ( ℃ ) | -20 ~ 200 -40 ~ 450 |

| Nominal pressure PN (MPa) | 1.6 4.0 6.4 |

| Allowable differential pressure(MPa) | ZSQP | Single action | 1.16 | 0.66 | 0.38 | 0.6 | 0.39 | 0.47 | 0.31 | 0.20 |

| Double action | 6.4 | 5.0 | 2.8 | 3.3 | 2.13 | 2.71 | 1.75 | 1.11 |

| ZSQM | Single action | Nominal pressure |

| Double action |

| ZSQN | Single action | 0.89 | 0.57 | 0.35 | 0.56 | 0.36 | 0.45 | 0.30 | 0.20 |

| Double action | 5.2 | 3.22 | 2.03 | 2.27 | 1.46 | 2.00 | 1.32 | 0.85 |

| Signal pressure (kPa) | 0 or 400 ~ 600 |

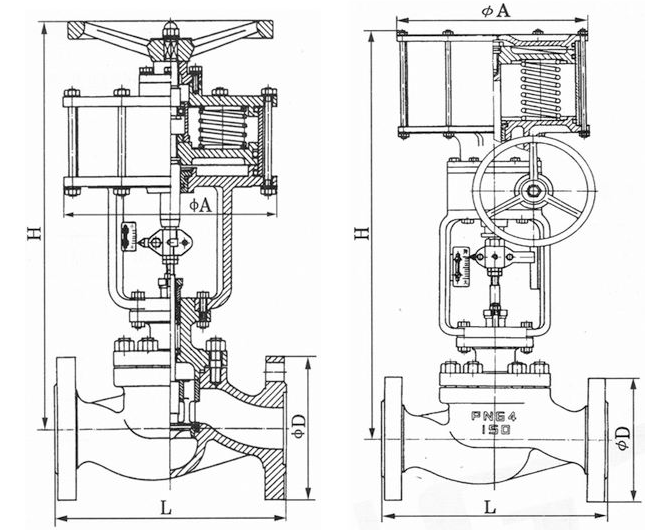

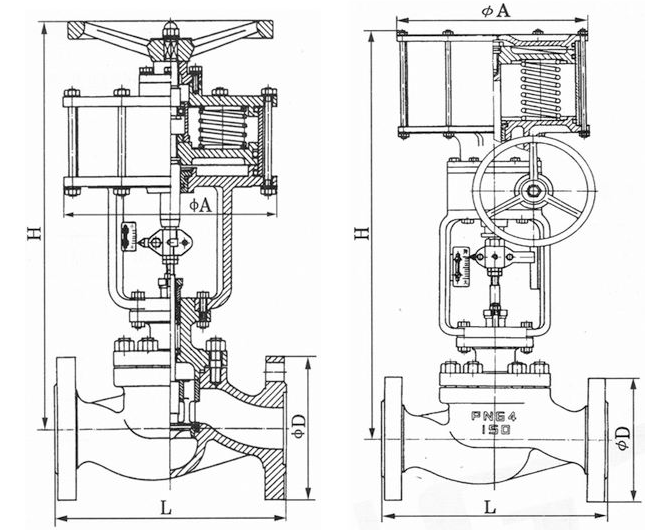

MAIN OVERALL CONNECTION DIMENSIONS

| Nominal diameter DN | L | A | H | L 1 | H 1 | A 1 | weight (Kg) | Signal connector internal thread |

|---|

| 20 | 150 | 130 | 220 | 80 | 115 | 100 | 10 | M10X1 |

| 25 | 160 | 130 | 220 | 80 | 120 | 100 | 12 |

| 32 | 180 | 150 | 235 | 80 | 130 | 100 | 15 |

| 40 | 200 | 150 | 235 | 95 | 138 | 120 | 18 |

| 50 | 230 | 150 | 240 | 95 | 155 | 120 | 25 |

| 65 | 290 | 280 | 250 | 105 | 178 | 160 | 30 |

| 80 | 310 | 280 | 260 | 105 | 207 | 160 | 40 |

| 100 | 350 | 280 | 265 | 105 | 222 | 160 | 60 |