PRODUCT OVERVIEW

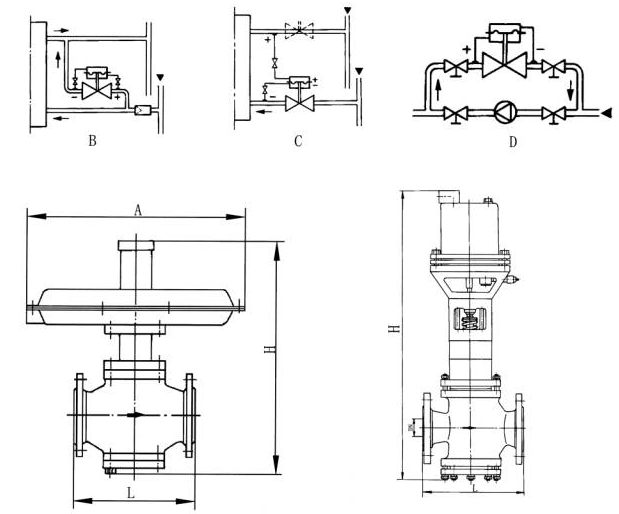

The self operated differential (micro) pressure regulating valve is an energy-saving product without external energy. The pressure change of the medium in the process pipeline is compared with the signal to balance the force of the regulated medium with the output force of the actuator, so as to achieve stable pressure and differential pressure. Zzcp-1 differential pressure valve adopts balanced single seat valve with stable pressure, high precision and good sealing. It is used to control micro differential pressure. Zzcn-10 differential pressure valve adopts double seat valve with large flow coefficient. The valve core can be assembled in front and upside down to form two different products. The product is suitable for controlling the mixing specific flow of two fuel gases in various industrial furnace combustion systems or in the sealing oil system of hydrogen cooled generator units. At the same time, it can also be used for the automatic control of pressure reduction, pressure stabilization or pressure relief of various industrial gases.

Zzvp micro pressure valve adopts balanced single seat valve, and the set value can be adjusted arbitrarily during operation. Therefore, it is suitable for micro pressure automatic regulation of fuel gas of combustion system of various industrial furnaces, petroleum products in process or protective gas of storage tanks and heat treatment in oil depots.

PRODUCT FEATURES

1. The micro pressure regulating valve does not need additional energy, and uses the pressure of the medium in the process pipeline to adjust itself, which is convenient and energy-saving;

2. The pressure subsection range is fine and cross each other, the adjustment accuracy is high, and the pressure setting value can be set continuously during operation;

3. For the pressure regulation behind the valve, the ratio between the pressure before the valve and the pressure behind the valve is 10:1 ~ 10:8;

4. Rubber diaphragm detection, high detection accuracy and sensitive action of actuator;

5. The pressure balance mechanism is adopted to make the regulating valve sensitive and accurate control.

MAIN TECHNICAL PARAMETERS AND PERFORMANCE INDEXES

| Nominal diameterDN(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|

| Rated flow(KV) | Single seat(P) | 8 | 11 | 20 | 32 | 50 | 80 | 100 | 160 |

| Double seat(N) | ─ | ─ | ─ | ─ | 50 | 83 | ─ | ─ |

| Rated stroke(mm) | 6 | 8 | 10 | 15 | 20 |

| Adjustment accuracy(%) | ±10 |

| Nominal pressurePN(MPa) | ZZC | 0.10、1.0 |

| ZZV | 0.10 |

| Medium temperature(℃) | ≤80 |

| Allowable leakage(L/h) | Single seat(P) | 10-4×Valve rated capacity |

| Double seat(N) | 10-3×Valve rated capacity |

| Pressure regulation range(Kpa) | 0.5~5.5、5~10、9~14、13~19、18~24、22~28、26~33、31~38、36~44、41~51、49~58、56~66、64~78、76~90、76~90 |

MATERIAL OF MAIN PARTS

| Material code | C(WCB) | P(304) | R(316) |

|---|

| Main parts | Valve body and bonnet | WCB(ZG230-450) | ZG1Cr18Ni9Ti(304) | ZG1Cr18Ni12Mo2Ti(316) |

| Valve core and valve seat | 1Cr18Ni9Ti(304) | 1Cr18Ni9Ti(304) | 1Cr18Ni12Mo2Ti(316) |

| Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| Filler | V-type polytetrafluoroethylene (F4), flexible graphite |

| Shim | Reinforced polytetrafluoroethylene (F4), stainless steel gasket, metal graphite spiral wound gasket |

| Upper and lower diaphragm covers | A3 steel plate stamping |

| Corrugated diaphragm | Nitrile rubber, oil resistant rubber, fluororubber |

| Spring | 60Si2Mn |

| Corrugated pipe | 1Cr18Ni9Ti |

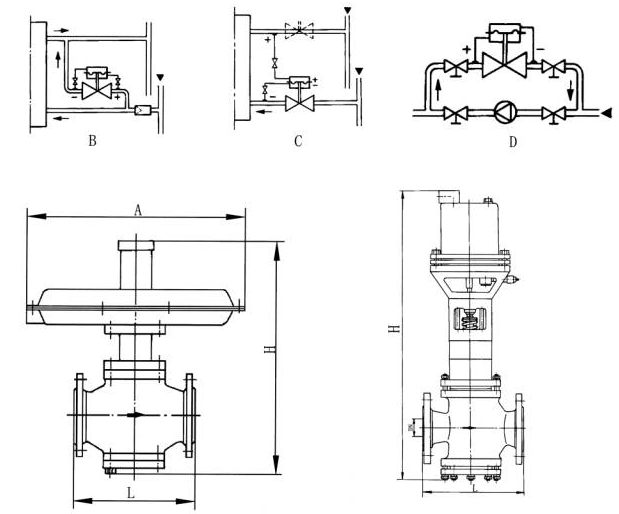

MAIN OVERALL DIMENSIONS AND WEIGHT

DN |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

A |

308 |

394 |

308 |

394 |

308 |

394 |

394 |

394 |

H |

ZZCP/ZZVP |

376 |

465 |

365 |

445 |

445 |

490 |

490 |

510 |

ZZCN |

536 |

536 |

|

|

|

|

|

|

L |

ZZCP/ZZVP |

150 |

160 |

180 |

200 |

230 |

290 |

310 |

350 |

ZZCN |

222 |

222 |

|

|

|

|

|

|

Weight g (kg) |

12 |

13 |

15 |

17 |

20 |

28 |

38 |

43 |

Lmpulse pipe threaded joint |

M16X1.5 |