PRODUCT OVERVIEW

Pneumatic three-way internal thread ball valve is suitable for pure pipelines such as food, beverage, medicine and chemical industry, as well as pipelines such as industrial environmental protection, water treatment, high-rise buildings, water supply and drainage. It can be divided into "L-type pneumatic internal thread ball valve" and "T-type pneumatic thread ball valve". L-type is suitable for the flow direction switching of media, which can connect two channels perpendicular to each other. T-type is suitable for the diversion, confluence or flow direction switching of media. The double-layer valve stem packing meets the German leakage test requirements. After the system pressure is relieved, it can be inspected and repaired without removing the whole valve body. Any port of the valve can be used as an inlet without leakage, and L-shaped or T-shaped channels can be made according to the working conditions. The pneumatic internal thread ball valve is easy to install.

PRODUCT FEATURES

1. Compact structure, quick opening and closing, smooth flow channel and small fluid resistance.

2. The sealing performance is good, and the elastic deformation of polytetrafluoroethylene, the material of four side valve seat, is used to realize leak free sealing.

3. One valve has multiple functions. Any port can be used as the inlet without leakage. The tee can be made into either L-shaped port or T-shaped port.

4. The maintenance is convenient. After the system is depressurized, the inspection and maintenance can be carried out without removing the whole valve body.

MAIN TECHNICAL PARAMETERS AND PERFORMANCE

| Nominal diameterDN(mm) | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

|---|

| Nominal pressure(MPa) | PN1.6、2.5、4.0、6.4 MPa |

| Valve body form | Three section split valve body |

| Connection form | Screw type |

| Spool form | "O" type spherical valve core |

| Action range | 0~90° |

| Leakage Q | According to GB / T4213-92, less than rated KV0.01% (soft seal: zero leakage) |

| Basic error | With positioner: less than ± 2% of full stroke |

| dead zone | With positioner: less than ± 2% of full stroke |

| Adjustable range | 250:1 |

| Configure actuator | GT、AT、ST、SR series single double acting pneumatic actuator |

| control mode | Switch two position control, 4 ~ 20mA analog signal control |

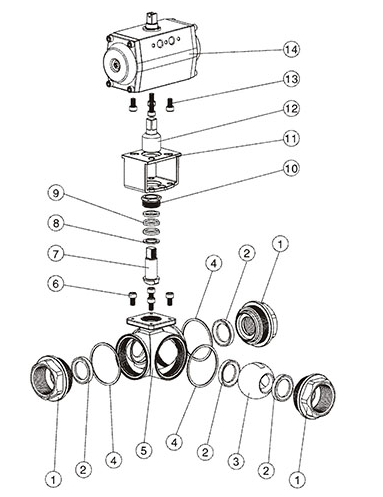

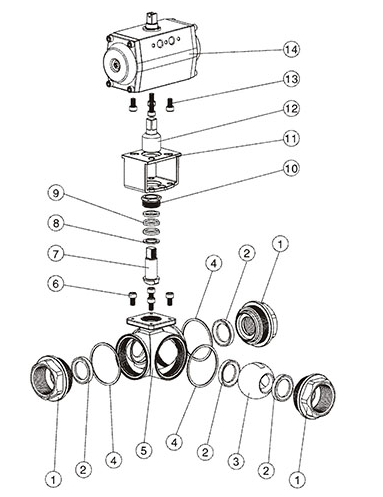

MATERIAL OF MAIN PARTS

|

Serial number |

Part name | Texture of material |

Serial number |

Part name |

Texture of material |

|

1 |

Joint |

Stainless steelCF8、CF8M、CF3、CF3M |

8 |

Shim |

Stainless steel304、316L |

|

2 |

valve seat |

PTFE、Nylon, para polyphenylene |

9 |

Filler |

PTFE |

|

3 |

sphere |

Stainless steel 304、304L、316、316L |

10 |

Gland |

Stainless steel 304、316L |

|

4 |

shim |

PTFE |

11 |

Connecting bracket |

Stainless steel CF8 |

|

5 |

valve body |

Stainless steel CF8、CF8M、CF3、CF3M |

12 | Connecting sleeve |

Stainless steel 304 |

|

6 |

Bolt |

Stainless steel 304 |

13 |

Bolt |

Stainless steel 304 |

|

7 |

Valve stem |

Stainless steel 304、304L、316、316L |

14 |

Pneumatic device |

Extruded aluminum alloy |

Remarks: the materials of main parts and sealing rings can also be designed and selected according to the actual working conditions or customer requirements.

MAIN CONNECTION DIMENSIONS

| Nominal diameter DN | inch NPS | Connection size |

|---|

| mm | inch (G) | L | L1 | H | A |

| 10 | 3/8" | 60 | 30 | 57 | 110 |

| 15 | 1/2" | 72 | 36 | 68 | 110 |

| 20 | 3/4" | 85 | 42 | 70 | 110 |

| 25 | 1" | 91 | 46 | 80 | 140 |

| 32 | 1-1/4" | 110 | 55 | 85 | 140 |

| 40 | 1-1/2" | 122 | 61 | 100 | 180 |

| 50 | 2" | 145 | 72 | 110 | 180 |