PRODUCT OVERVIEW

The pneumatic cast steel fixed ball valve adopts the design of upper and lower valve stems, fixed valve cores (shaft supported) and movable sealing seats. More stable operation, with automatic compensation function, no gap between two-way sealing seats, great shear force and self-cleaning function when rotating. It is especially suitable for on-off of imperial fibers, suspensions with small solid particles and viscous media. This product can be widely used in the automatic control system of papermaking, petrochemical, chemical industry, metallurgy, electric power, environmental protection, petroleum, light industry and other industrial departments.

PRODUCT FEATURES

1. The fixed ball design is adopted, and the relative moving parts are made of self-lubricating materials with minimal friction coefficient, so the operating torque is small. In addition, the long-term sealing of sealing grease makes the operation more flexible.

2. Adopting high platform structure and ISO5211 connection standard can make the installation of electric / pneumatic actuator more professional.

3. Full bore design is adopted, with small flow resistance.

4. It adopts bidirectional metal movable sealing structure, with automatic compensation and self-cleaning functions, and good sealing performance

5. The fixed ball design is adopted, and the preload spring is added, so that the ball valve has the function of automatic pressure relief.

6. Each ball valve has two movable sealing seats, which can be sealed in both directions, so the flow direction of medium does not need to be considered during installation.

7. It has a fire-proof and anti-static structure, and a conductive spring is set between the valve rod and the valve body and between the valve rod and the ball to avoid static ignition and ignition of flammable media. Ensure system security.

8. The fire-resistant structure has double protection. In case of fire and burning of the sealing ring, each sealing part of the ball valve can form a metal to metal hard sealing structure.

9. Automatic pressure relief structure: when the liquid medium retained in the valve cavity is gasified due to the increase of temperature, so that the pressure in the valve cavity increases abnormally, the medium in the valve cavity can automatically relieve the pressure by pushing the valve seat with its own thrust, so as to ensure the safety of the valve.

MAIN PERFORMANCE SPECIFICATIONS

Nominal diameterDN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 |

Allowable differential pressure(MPa) | ≤Nominal pressure |

Action range | 0~90° |

Leakage Q | Soft seal class VI, hard seal class IV, in accordance with ANSI b16.104 |

Basic error | With positioner: less than ± 2% of full stroke |

Return difference | With positioner: less than ± 2% of full stroke |

MAIN TECHNICAL PARAMETERS

Valve body form | Three stage cast valve body |

Nominal diameter | DN50~1000mm |

Nominal pressure | PN1.6、2.5、4.0、6.4、10.0 MPa;ANSI 150 300 600 900 LB;JIS 10 20 30 40 K |

Connection form | Flange type |

Flange standard | JIS、ANSI、GB、JB、HGetc. |

Bonnet form | Integrated |

Gland type | Bolt compression type |

Sealing packing | V-type polytetrafluoroethylene filler, impregnated polytetrafluoroethylene asbestos filler, asbestos textile filler and graphite filler |

VALVE TRIM

Spool form | O-type fixed ball valve core |

Flow characteristics | Approximate quick opening type |

EXECUTING AGENCY

Actuator model | GT、SR、ST、AT、AW Series single and double acting pneumatic actuator |

Air supply pressure | 0.4~0.7MPa |

air connection | G1/4"、G1/8"、G3/8"、G1/2" |

ambient temperature | -20~+90℃ |

Action form | Single acting actuator: air closed (B) -- valve position open (FO) in case of gas loss; Gas open (K) -- valve position closed (FC) in case of gas loss Double acting actuator: air closing (B) -- valve position holding (FL) in case of gas loss; Gas open (K) -- valve position hold (FL) in case of gas loss

|

Accessories available | Positioner, solenoid valve, air filter pressure reducer, holding valve, travel switch, valve position transmitter, handwheel mechanism, etc |

MATERIAL OF MAIN PARTS

1 | base | WCB、CF8、CF8M、CF3M |

2 | Left valve body | WCB、CF8、CF8M、CF3M |

3 | Lower valve shaft | 2Cr13、304、316、316L |

4 | Right valve body | WCB、CF8、CF8M、CF3M |

5 | sphere | 2Cr13、304、316、316L |

6 | seal ring | PTFE、PPL、304、316、316L |

7 | Spring | 65Mn、stainless steel |

8 | pin | 25、35、45 |

9 | Upper valve shaft | 2Cr13、304、316、316L |

10 | Bracket | WCB、CF8、CF8M、CF3M |

11 | Packing pressing plate | WCB、CF8、CF8M、CF3M |

12 | Actuator | Provide configuration according to customer requirements |

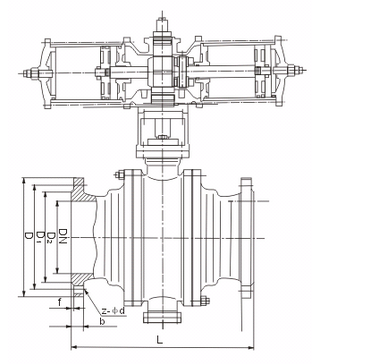

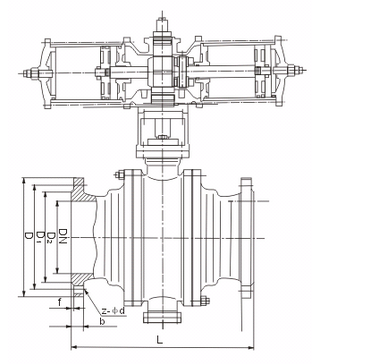

MAIN GENERATOR INSTALLATION DIMENSION TABLE

Nominal diameterDN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 |

L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 |

H | - | - | - | - | - | - | 335 | 385 | 430 | 470 | 590 | 700 | 780 | 950 |

H1 | Depending on the equipped actuator, the connection size is different with different actuators |

A |

D | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 705 | 840 | 910 |

D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 650 | 770 | 840 |

D2 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | 435 | 485 | 608 | 718 | 788 |

n-φd | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | 12-26 | 12-30 | 12-34 | 12-41 | 12-41 |